Safety Reference Guide

This Reference Guide is based on the Track Access Safety Program. It provides a means for employees and contractors to work safely within the Light Rail Right-of-Way. It helps minimize the dangers inherent to working around moving trains by providing guidance on the use of personal protective equipment, proper safe behavior near train tracks, and basic communication skills with train operators.

This Reference Guide is based on the Track Access Safety Program. It provides a means for employees and contractors to work safely within the Light Rail Right-of-Way. It helps minimize the dangers inherent to working around moving trains by providing guidance on the use of personal protective equipment, proper safe behavior near train tracks, and basic communication skills with train operators.

No individuals are permitted to work within the Light Rail Right-of-Way without permission from the Operations Control Center. The Right-of-Way is the Hampton Roads Transit owned property along the Light Rail System, including mainline tracks, yard tracks, shop tracks, and stations. The Operating Right-of-Way is defined as 12 feet from centerline to either side of the train track. All persons needing access to the Right-of-Way are required to have Track Access Level 1 training except in instances where emergency access is required. In those instances, the Operations Control Center will authorize any emergency work. This reference guide is a companion to the Track Access Safety Training and OPS-LRTP 101.13 Work Performed on the Tide ROW.

All employees and contractors are expected to adhere to Hampton Roads Transit’s rules and procedures to keep them safe while working on The Tide alignment.

Personal Protective Equipment (PPE)

All workers must wear Safety Vests that comply with ANSI performance class II with an X on the rear of the vest and Safety Boots with ankle support that are electrical hazard rated at all times when on or within the Right-of-Way as specified in OPS-LRTP 101.13 Work Performed on the Tide ROW.

Other PPE:

- Hard Hat (if applicable)

- Safety Glasses (if applicable)

- Other PPE as required based on the work to be performed

Safety Around Tracks and Switches

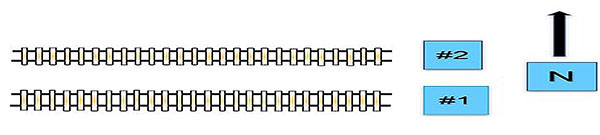

When walking on tracks, all workers must walk facing oncoming traffic. Workers must never walk with your back facing oncoming traffic when on the Right-of-Way. Track #1 is the Eastbound Track from EVMC to Newtown. Track #2 is the Westbound Track from Newtown to EVMC.

No worker shall:

- Stand

- Step

- Sit

- Walk or run on the rails

Training Required

Level 1 – Required to perform work on or within the Right-of-Way.

Level 2 – Required to perform work as a flag person on or within the Right-of-Way.

Level 3 – Required to operate a Hi-Rail vehicle or On-Track Equipment on or within the Right-of-Way.

Overhead Catenary System (OCS)

The Overhead Catenary System (OCS) consists of:

- Traction Power Substations

- Electrified overhead wires

- Feeder Cables

- Negative Return wires

The electric overhead wires are energized with 750vdc of electricity. Workers must maintain a 10-foot clearance from any overhead wires. OCS wires must be considered energized unless it is field verified that it is de-energized.

Railroad Communication

Train Operators will sound four (4) short horn blasts to request a hand signal.

Train Operators will sound (2) two short horn blasts to acknowledge understanding of hand signals.

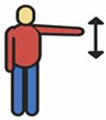

Arm swung horizontally at right angle to the track, indicates to the train operator that they must stop.

Arm raised and lowered vertically indicates to the train operator that all workers and items are clear and to proceed through the area.

Arm raised held horizontally at arm’s length.

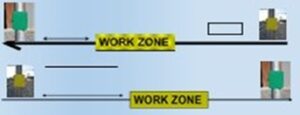

Workers must stay in the authorized work zone unless authorized by OCC and accompanied by a Level 2 qualified flag person.

No Clearances Areas

No Clearance Areas are areas where there is not enough space between the train and the worker to allow the safe passage of trains with a worker present. Workers must NEVER allow trains to pass while working within a No Clearance Area.

For more information regarding the flag persons responsibility, consult the OPS-LRTP 103.03 Flag Person Duties.